Sanitary

Sanitary, Stainless Steel Tanks for the Food/Dairy Industry including the Pharmaceutical Industry

Count on Stainless Steel Technologies and Pressure Vessels we meet or exceed to get the job done

Count on SST-PV to design and build commercial and industrial stainless steel storage tanks that meets or exceeds the USDA standards.

SST-PV partners with clients to determine the size and style of tanks right for the operation.

All tanks feature a superior stainless- steel finishing process. your tanks’ design will meet all your expectations, they look immaculate, and withstand a life time.

Pharmaceutical

Stainless Steel and Pressure Vessels have designed and fabricated several pharmaceutical skidded systems.

We will fabricate to your design or ours and have the skid ready to be installed in your plant.

Stainless Steel and Pressure Vessels also provides:

- WPS- Welding Procedure Specification

- PQP-Product Quality Plan

- WPQ- Welder Performance Qualification

- and weld maps Radiographic and Borescope,

- ASME BPE/Pharm/Bio Industries, gas and material certifications.

Mixing Tank and Batch Tank manufacturer

Stainless steel mixing and batch tanks are used by virtually all industries and can be found in practically every production line no matter what is being produced.

SST-PV has the experience and expertise to design mixing and batch tanks specifically for your application.

We work with customers from diverse group of industries, which has led us to develop an expansive range of offerings.

Mix Tank design and fabrication

Whether you’re producing chemicals and want mill finish or you’re making pharmaceuticals and heed a highly sanitary electropolish finish and dimpled heat transfer surface.

SST-PV can design and build your batching and mixing vessels.

Options Include

- Agitation system for a variety of mixers and stainless steel bath tanks

- variety of stainless steel and other nickel alloy materials available

- ASME certified welders and weld procedures

- various material and weld finish’s for tank interior and exterior

- heating and cooling options; single or double wall construction

- tank supports (legs, lugs, skirts, saddles, flat pitch)

- various manways and fittings

- components

- sight glasses and lights

- CIP systems

- no foam inlets

- downtube

- thermowells

- outlet valves

- and much more

SST-PV will design and build your mix tank fully equipped with agitation.

We also provide them prepared for field installation of customer furnished mixers.

Your Partner in Tank Manufacturing

For 22 years, SST-PV has worked with engineering firms, design-build contractors, mechanical contractors, site managers, and business owners to solve problems for a wide variety of industries including poultry, dairy, food and warehousing.

Many of our customers are on tight deadlines and often need to order stainless steel tanks and parts with virtually no time to wait.

The SST-PV team is experienced, many with backgrounds in our customers industries. Time sensitivity and availability is important to all of us.

We’re ready to make your tank a priority, so you get what you need to keep your project moving.

At times, we may ship you a partial shipment so you can keep working while we locate or manufacture the remaining order.

Stainless steel tanks are available in a variety of sizes, styles and options to fit your needs, and keep your operation moving ahead.

SST-PV Tank is offering is limited quantity available in stock.

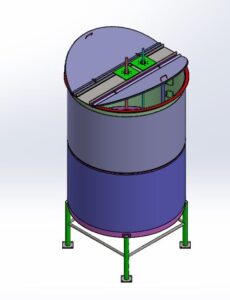

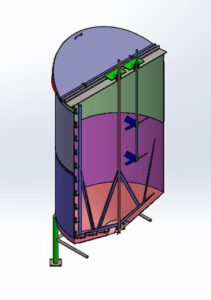

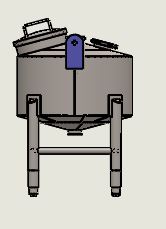

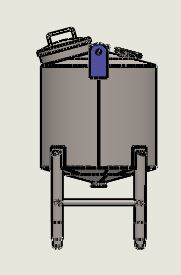

Sanitary Cone Top and Bottom Head Tanks

Sanitary Cone Top and Bottom head tanks can be customer designed with legs that feature adjustable ball feet.

Our stainless steel tanks are fabricated to meet sanitary standards to help you meet all your requirements.

- You can either purchase in 304 or 316 stainless steel

- 3/4″ radius corners for easy cleaning

- 2B or #4 finish inside and out

These tanks are more cost efficient and shorter lead times

- PART # 55001A

- OVERALL HEIGHT 38″ TALL

- WEIGHT 1896 LBS

- PART# 55002A

- OVERALL HEIGHT 48″

- WEIGHT 3609 LBS

- PART # 55003A

- OVERALL HEIGHT 47″ TALL

- WEIGHT 7063LBS

- PART # 55004A

- OVERALL HEIGHT 66″ TALL

- WEIGHT 13859 LBS

- PART NUMBER# 55005A

- OVERALL HEIGHT 77″ TALL

- WEIGHT 19698 LBS